Abstract

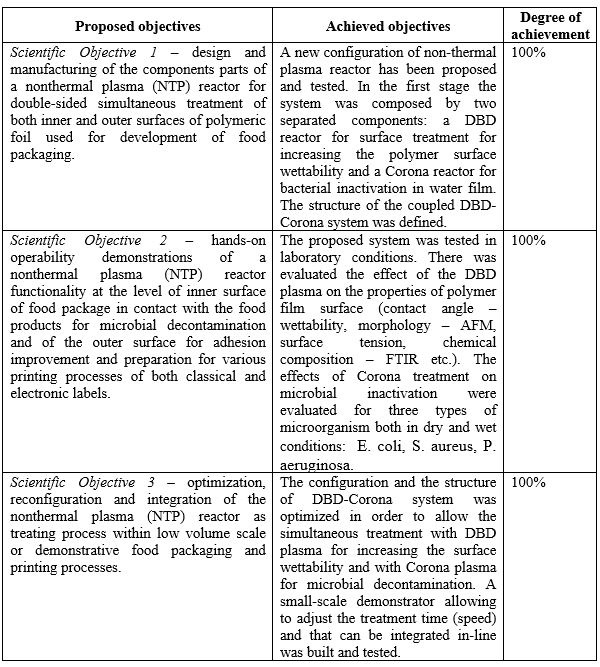

The advantages of polymeric food packaging are widely recognized but concerns on food contamination as of improper sterilisation and/or disinfection of inner-surface of polymer in contact with food may represent a major risk in food safety. On the other hand, the next generation of food packaging should be suitable for incorporating e-labels and smart labels for improved traceability of the food products. The most important issue is related to both inner and outer surfaces of polymeric foil treatment, playing an important role in packaging and should satisfy the expectations in respect to food safety and attractive labelling. In this regard, non-thermal plasma (NTP) emerged as technology capable of increasing the surface energy of polymers, enhancing adhesion and printability, and has been successfully applied for surface decontamination of both foodstuffs and food packaging. Accordingly, PlasmaPack aims to develop a treating technology based on NTP plasma (coupled DBD-Corona discharges) for double-sided treatment of polymeric foil used in food packaging. This will lead to proper disinfection (sterilisation) of inner surface and facilitates smart labels printing on outer surface.

Keywords

Flexible production and manufacturing

Precision engineering

Surfaces

Project implementation work packages:

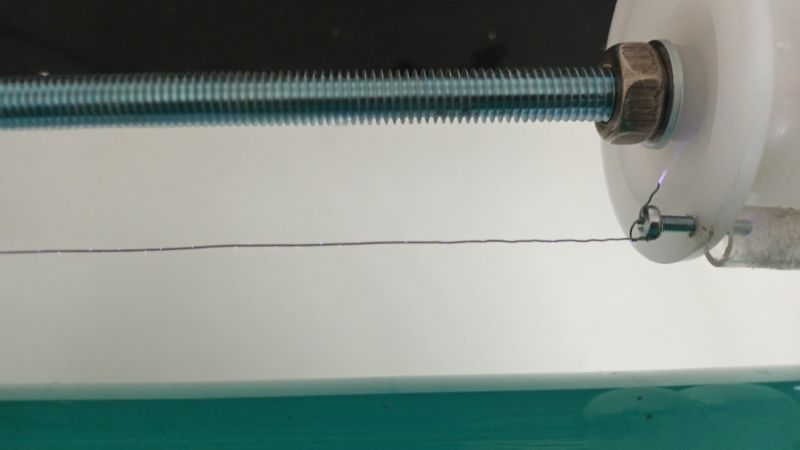

WP1. Personalized cold plasma reactor requirements identification, design and in-house fabrication

Expected results:

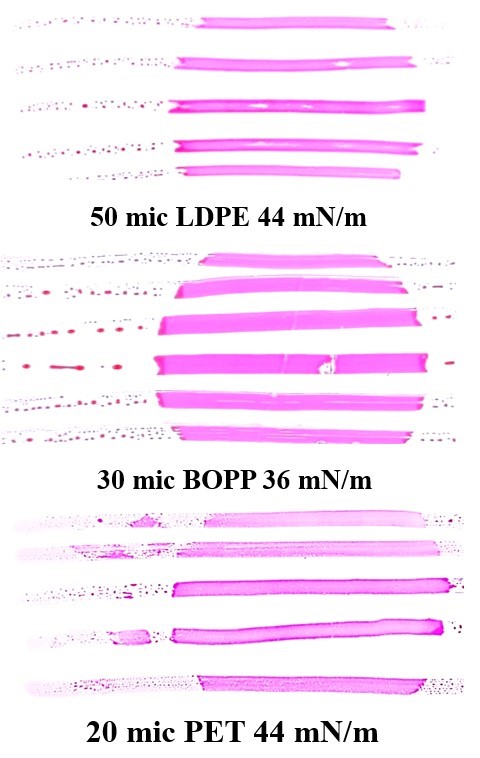

WP2. Assessment of pre-treatment effect on inner and outer surface of polymeric substrates employed - validation in laboratory working conditions

Expected results:

WP3. Assessment of pre-treatment effects on inner-surface structural modifications of various polymers with respect to quality of the food packaging

Expected results:

WP4. Optimization of DBD-Corona non-thermal plasma architecture and design and evaluation of process integration possibilities

Expected results:

WP5. Demonstrative evaluation of integration possibilities of DBD-Corona non-thermal plasma technology at pre-industrial scale

Expected results: